HengYao

was established in 2018

Our company majors in the research, development and production of breathable film, breathable printing film, nonwoven and laminated film. And possesses a total production capacity of 15,000 tons of breathable material. For nonwoven, we adopts international advanced technology and equipments and advanced software and management technology, establish the internationally advanced level of light-weight 10-60 g/㎡ SS/SMS, ES hot air through nonwoven fabric production lines.

To set up professional nationwide first new materials hygienic products center for development goals. We continue to strengthen and improve technology content , added value and becoming more competitive products.

Company Video

OEM / ODM SERVICE

We provide professional OEM and ODM service to meet your needs

-

20+years

Technical Team Experience

-

10000+tons

Annual Output

-

160

Number of employees

-

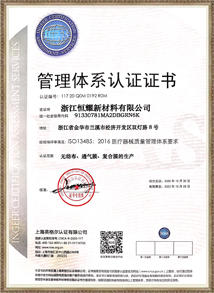

xx+

Honor

News

-

26 Apr

The Role of Nonwoven Fabric in Personal Protective Equipment

China High Quality Nonwoven Fabric For Sale Personal protective equipment (PPE) is essential for protecting workers in a...

Read more -

19 Apr

The Benefits of Breathable Composite Film for Medical Device Packaging

Wholesale Design Breathable Composite Film Exporter When it comes to medical device packaging, it's essential to use mat...

Read more -

12 Apr

Understanding the Role of Diaper Backsheet Film in Absorbency and Fit

Sale OEM Diaper Backsheet Film Supplier When it comes to diaper design, one of the critical components is the backsheet ...

Read more -

05 Apr

The Science Behind Breathable Film

China High Quality Breathable Film Producer China Breathable Film is a unique and innovative material that has gained po...

Read more

English

English 中文简体

中文简体 Português

Português 日本語

日本語

Request A Quote

Request A Quote